ball mill mining تنزانيا

مجال التطبيق

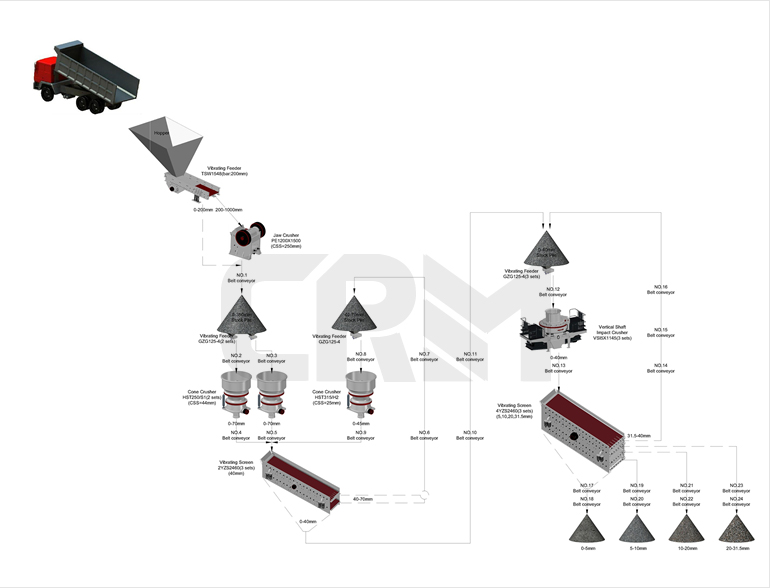

خط إنتاج معالجة البوكسيت 200TPH في غينيا

تم الإشادة بنظام التحكم الذكي Liming Heavy Industry. تمكننا من مراقبة خط الإنتاج المحلي في الوقت الفعلي ومعرفة معلومات الموقع في الوقت المناسب ، مما يوفر راحة كبيرة لإدارتنا.

المعدات: كسارة فكية PE750x1060 ، كسارة مخروطية هيدروليكية HPT300

المواد: البوكسيت

السعة: 200 طن / ساعة

حجم المدخلات: 600 مم

حجم الإخراج: 0-20mm.

التطبيق: إنتاج سبائك الألومنيوم ، التصنيع الحراري

China TANGSHAN MINE MACHINERY FACTORY company profile - Ball Mill; Mining

Tangshan Mine Machinery Factory is a specialized manufacturer that produces complete sets of equipment for metallurgy, mining, building materials, environmental protection, as

TANGSHAN MINE MACHINERY FACTORY Factory Tour - Ball Mill; Mining

Ball Mill Quality Report. Contact Details. TANGSHAN MINE MACHINERY FACTORY. Contact Person: Amy. Tel: 0086 15600215719. Send your inquiry directly to us. Contact

Ball Mill SpringerLink

2023年4月30日 Ball mill is a type of grinding equipment that uses the rotary cylinder to bring the grinding medium and materials to a certain height and make them squeeze,

Ball Mill Maintenance Process and Methods Mining Pedia

2023年7月18日 The ball mill is a common grinding equipment, widely used in industries such as mining, building materials, and chemical engineering for material grinding. The

Predictive maintenance on ball mill liner using 3D scanner

2023年12月1日 The ball mill is an important part of the grinder in the mining industry. Maintenance is required for the machine to continue to work effectively and optimally.

Ball milling – A green and sustainable technique for the preparation

2022年1月1日 The ball milling method is classified as vibration mill, planetary mill and magneto-ball mill depending on the movement of the balls and vessel and among them,

Scale-Up Problems With Large Ball Mills Mining, Metallurgy

Analysis of ball and pulp flow in ball mills indicates that three factors may become critical with increasing mill diameters: ball size, fraction critical speed, and average pulp flow

Steel Grinding balls an optimal choice for mining in ball mills.

2023年11月23日 Steel grinding balls are essential in the mining industry for grinding raw materials into fine powders. They are used in ball mills, which are critical components in

Ball Mill Ball Mills Wet Dry Grinding DOVE

5 天之前 DOVE small Ball Mills designed for laboratories ball milling process are supplied in 4 models, capacity range of (200g/h-1000 g/h). For small to large scale operations, DOVE Ball Mills are supplied in 17

Understanding the SAG Mill in Copper Ore Mining Process

2023年10月10日 A SAG mill, or semi-autogenous grinding mill, is a type of machine used in mining and mineral processing operations. It uses the crushing and grinding action of rocks to reduce materials such as copper ore into smaller pieces for further processing. Unlike traditional mills that rely on steel balls or other media to break down materials,

Ball Grinding Process SpringerLink

2023年7月27日 Ball grinding process is a grinding method of crushing ore with ball-shaped grinding medium in the grinding mill. In the ball grinding process, because the steel ball has 360° free rotation, it is suitable for falling motion and throwing motion. When the rotating speed of the cylinder is low, the medium rises to a certain height along the ...

Ball Mills Manufacturer - JXSC

Applying steel balls as grinding media, our ball mills or ball grinding machines are widely applied in mining, construction, and aggregate applications. Since 1985, JXSC has been a leading ball mill manufacturer, providing premium services, from RD and production to installation and free operation training. Inquiry Now.

Mining Balls: The Backbone of Material Processing

2023年10月4日 Grinding balls are spherical components used in grinding mills to crush and grind raw materials, turning them into fine powders. These balls are essential in the mining industry to extract valuable minerals from ore. Steel Grinding Balls: Steel grinding balls are a subset of grinding balls, specifically made from high-quality steel.

Ball Mill - an overview ScienceDirect Topics

Quantum Nanostructures (QDs): An Overview. D. Sumanth Kumar, ... H.M. Mahesh, in Synthesis of Inorganic Nanomaterials, 2018 3.6.1.1 Ball Milling. A ball mill is a type of grinder used to grind and blend bulk material into QDs/nanosize using different sized balls. The working principle is simple; impact and attrition size reduction take place as the ball

What is a Ball Mill? Economy Ball Mill

2023年6月12日 What is a Ball Mill? A ball mill is a type of grinder that uses metal balls or other grinding mediums to reduce the size of various materials. The material to be ground is placed in a cylindrical container that spins on its axis. The metal balls or grinding media inside the container hits the material and breaks it down into smaller particles.

Ball Mill SpringerLink

2023年4月30日 Ball mill is the key equipment for crushing materials after they are crushed. It is widely used in cement, silicate products, new building materials, refractories, chemical fertilizer, ferrous and nonferrous metals mineral processing, powder metallurgy, glass ceramics, and other production. Dry grinding or wet grinding can be carried out for ...

Ball Mill Maintenance Process and Methods Mining Pedia

2023年7月18日 When maintaining the ball mill, the following tools and equipment may be helpful: 1. Wrench: used to disassemble and install fastening bolts, nuts, and other components.. 2. Lubricating oil gun: used to add lubricating oil to bearings, gears, transmission devices, and other parts.. 3. Lubricating oil: selecting appropriate lubricating

Ball milling in organic synthesis: solutions and challenges

During the last decade numerous protocols have been published using the method of ball milling for synthesis all over the field of organic chemistry. However, compared to other methods leaving their marks on the road to sustainable synthesis (e.g. microwave, ultrasound, ionic liquids) chemistry in ball mills is rather underrepresented in the ...

Recent advances in the treatment of contaminated soils by ball

2022年3月15日 Ball mill is an excellent immobilization technique. ... methods to corroborate that the ball milling treatment has achieved soil remediation in multi-metal contaminated mining areas (Concas et al., 2020a). Results show that the leaching concentrations of Al, As, Pb, and Hg was below the drinking water regulatory thresholds

The Ultimate Guide to Ball Mills - Mining-pedia

2019年8月14日 5. The size of the ball mill is large, and it is necessary to carry out lifting work during the process of replacing the ball mill liner. The hoisting ball mill liner is the responsibility of the hoist. The lifting process requires attention to the operation of the wire rope and the hook. 6.

Ball Mill - RETSCH - powerful grinding and homogenization

Planetary Ball Mills. Sample volumes up to 4 x 220 ml. Final fineness*: 0.1 µm. Extremely high centrifugal forces result in high energy input. Dry and wet grinding by impact and friction. To the product range. Ultrafine grinding with up to 76 g.

Ball Mill - Durable Mining Machine

The ball mill is a crucial grinding equipment widely used in mining, metallurgy, chemicals, building materials, and other industries. It is primarily designed to fine-grind materials, meeting the subsequent process’s particle size requirements. The ball mill achieves this by utilizing the impact and grinding action of steel balls within its ...

辉县市孟庄镇全兴矿山机械厂

2023年7月3日 ABOUT US. Henan Xinxiang Huixian City Mengzhuang Town Quanxing Mining Machinery Factory was established in 1997, is a professional customization, production of a variety of steel casting and mechanical processing enterprises, the company has professional experience in the casting process team, superb excellent technical

Used Ball-mills For Sale - A.M. King

UNUSED METSO 22' x 38' (6706mm x 11582mm) Ball Mill, 10,000 kW (13,410 HP) Twin Pinion 50 Hz Motors and Gear Reducers. Inventory ID: 6C-CM02. UNUSED METSO 22' x 38' (6706mm x 11582mm) Ball Mill, 10,000 kW (13,410 HP) Twin Pinion 50 Hz Motors and Gear Reducers. Manufacturer: METSO OUTOTEC.

2024 Ball Mill (Mining) Market Analysis 2032 - LinkedIn

2024年3月13日 The global Ball Mill (Mining) market is valued at USD 462.5 million in 2019. The market size will reach USD 459.2 million by the end of 2026, growing at a CAGR of -0.1% during 2021-2026. Global ...

Mining Mills AllMinings

2024年2月22日 Mining mills play a critical role in the mineral processing industry, serving as the primary equipment for reducing the size of ore particles. It provides an overview of the latest advancements in mining mill technology, with a focus on improving efficiency, sustainability, and innovation. Efficiency in mining mills is paramount, as it directly ...

An Energy-T75 Size Reduction Model for Ball Mills Mining,

2022年12月22日 The JKFBC test relates to ball mills in the sense that balls are used as grinding media in both cases and that breakage is performed both in compression. The particle sizes tested in JKFBC (0.106–4.75 mm) represent about 70–80% of the feed particle mass, equal to the mass entering a secondary grinding ball mill.

Mining Ball Mill Grinders Manufacturing and Suppliers in

2023年2月9日 Mining ball mill grinders are essential tools in the mineral extraction process, especially in South Africa, where mining is a major industry. These grinders are used to grind various minerals and raw materials into a fine powder that can then be used for further processing. In this article, we will provide a comprehensive overview of the ...

2-12-24SERVICE MECHANISM

Common choice of more than 170 countries

Email:[email protected]

المحادثة على الإنترنت

المحادثة على الإنترنت